Electrical trace heating or as it is often called heat tracing refers to the process of maintaining or raising the temperature of instrument impulse lines pipes and even vessels through specially designed cables.

Electrical heat tracing basics.

Minimum ambient temperature ta.

Electrical trace heating or as it is often called heat tracing refers to the process of maintaining or raising the temperature of instrument impulse lines pipes and even vessels through specially designed cables.

In simple terms it the application of a compensating heat source.

Petrochemical plants have many thousands of feet of electric heat tracing.

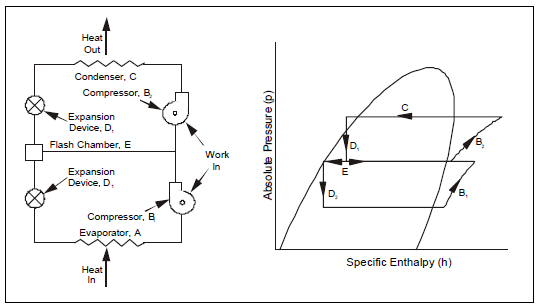

Heat loss calculations 2.

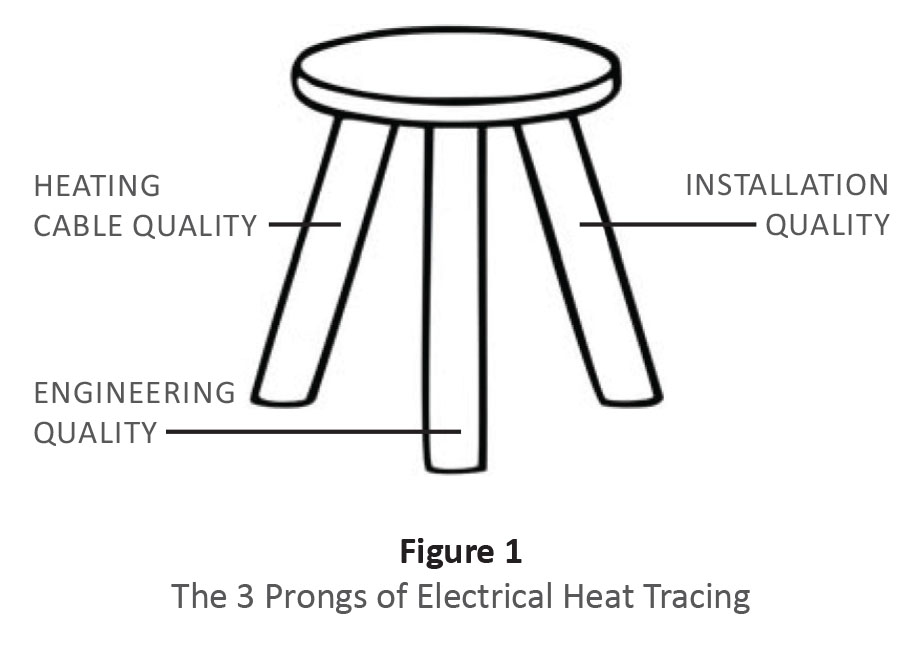

Heating fundamentals before plunging headfirst into a myriad of heat trace designs products and applications one must first have an understanding of the basics of heat loss and why heat trace products are used.

Collect the following data for each pipe for tank applications go to page 6.

Winterization protection protects lines and vessels from freezing during the colder months.

Maintenance temperature t m.

Heat transfer basics rich hulett 1.

Current heat trace technology utilizes a self regulating polymer that controls the wattage of the element.

Ieee electrical heat trace fundamentals tutorial abstract.

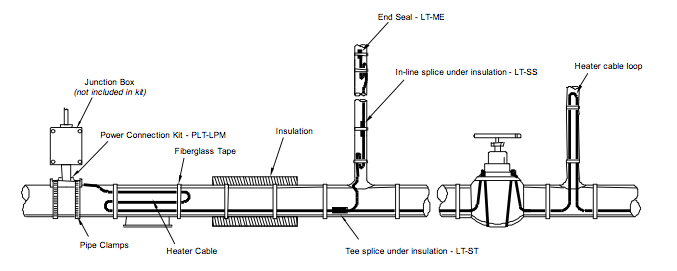

Electric heat tracing heat tape or surface heating is a system used to maintain or raise the temperature of pipes and vessels using heat tracing cables.

In simple terms the application of a compensating heat source.

Process heating keeps the pipes and vessels warm to enable the system to function properly.

Trace heating may be used to protect pipes from freezing to maintai.

Electrical trace heating system basics.

Heat trace is an electrical system used to maintain or raise the temperature of pipes and vessels.

The pipe is usually covered with thermal insulation to retain heat losses from the pipe.

Heat generated by the element then maintains the temperature of the pipe.

Heat tracing product training manual chromalox training chapter 1.

The topics covered are as follows.

The first step in designing a heat trace system is to determine the heat loss from each pipe or tank to be traced.

This section deals with the basic principles of heat transfer.

The electric heating is achieved by utilizing a resistant element that is run alongside the piping or vessel.

Then fol low the steps below to determine the heat loss.

It s used primarily for winterization or process heating.

Trace heating takes the form of an electrical heating element run in physical contact along the length of a pipe.